Gold elution might sound like a complicated chemical process, but at its core, it’s the moment where all the hard work of gold recovery finally pays off. It’s the step that turns loaded carbon into actual gold, the payoff stage that determines how much value a mining operation truly captures.

If mining is the art of digging up opportunity, elution is the science of turning it into profit.

Understanding Gold Elution

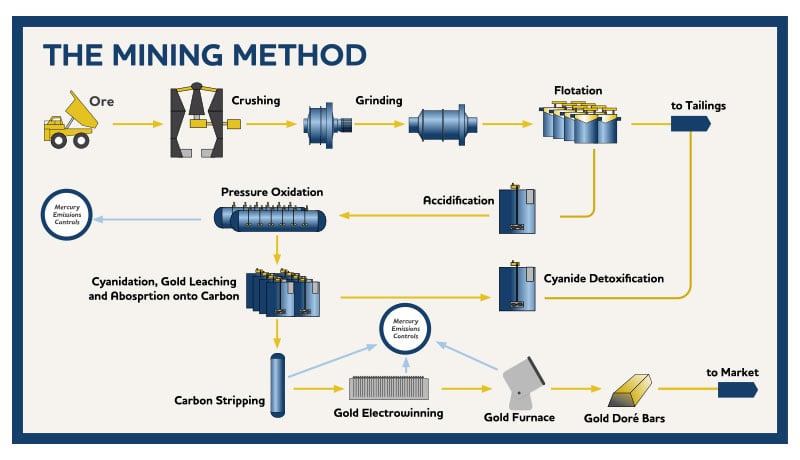

To put it simply, gold elution is the process of stripping gold from activated carbon.

During the carbon-in-pulp (CIP) or carbon-in-leach (CIL) stages, gold particles attach themselves to activated carbon granules in a slurry. That loaded carbon is then transferred to the elution circuit, where controlled heat, pressure, and chemical solutions “desorb” the gold.

In plain English, elution reverses the adsorption process.

Gold that was “stuck” to carbon is freed, dissolved into a solution, and later recovered through electrowinning and smelting.

It’s one of the final, most precise steps in gold processing, and when done right, it determines both yield and purity.

Why the Elution Process Matters So Much

Many people outside the industry underestimate how critical elution really is. But anyone who’s been around a plant knows: a single elution run can make or break production numbers for the week.

Here’s why it’s the heart of the recovery process:

- It controls your gold recovery rate.

Even small inefficiencies during elution can leave gold trapped in carbon, meaning lost profit. - It defines your purity.

A clean, consistent elution ensures that the recovered gold has minimal contamination from base metals or impurities. - It affects turnaround time.

A well-run elution system means faster batches, less downtime, and smoother operation for the entire mine. - It directly reflects plant expertise.

Skilled control of temperature, pressure, and chemical dosing separates professional operators from those who still “hope for the best.”

The Science Behind It

The process begins by heating a caustic cyanide solution (usually a mix of sodium hydroxide and sodium cyanide) to specific temperatures. This solution passes through the loaded carbon in the column, releasing gold ions back into liquid form.

Once stripped, that “pregnant” solution, rich in gold, flows into the electrowinning cell, where electric current plates out the gold onto steel wool cathodes.

Finally, the gold is washed, dried, and smelted into doré bars.

Every step relies on balance:

-

Too much heat can damage the carbon.

-

Too little can leave gold behind.

-

Poor pressure or flow can create uneven stripping.

That’s why consistency, calibration, and monitoring are everything in elution.

Different Elution Systems: ZADRA vs AARL

Most plants in Zimbabwe use either the ZADRA or AARL system.

-

ZADRA is a continuous process, relatively simple and efficient, suited to smaller operations.

-

AARL (Anglo American Research Laboratories) is a more advanced batch process known for faster stripping and higher recovery, ideal for larger mines.

Each has its place, but both rely on tight temperature control and well-maintained carbon to perform properly.

At Bulawayo Elutions, we’ve refined both systems over the years, customizing process parameters to suit each client’s ore type, water chemistry, and plant setup.

Why Experience Matters in Elution

You can’t fake experience in this line of work. The process might look simple on paper, but real-world results depend on decades of trial, observation, and calibration.

A skilled elution team knows how to:

-

Identify subtle temperature drops before they cause recovery losses.

-

Reactivate carbon to restore adsorption performance.

-

Balance chemical use to avoid unnecessary cost or contamination.

-

Manage water quality, a critical but often ignored factor in Zimbabwe’s mining environments.

That’s what separates a smooth, high-yield elution from one that struggles with inefficiency and loss.

Why Choose a Local Bulawayo Elution Company

For most miners in Zimbabwe, transporting loaded carbon to distant facilities adds unnecessary cost, risk, and time.

Working with a local elution company in Bulawayo means:

-

Faster turnaround on every batch.

-

Easier communication and transparency.

-

Access to experienced technicians familiar with local ore conditions.

-

Peace of mind knowing your gold never leaves the country.

At Bulawayo Elutions, we built our operation on three promises: consistency, accuracy, and trust. Every load we process is handled with the same precision we’d expect if it were our own.

Final Thoughts

Gold elution isn’t just another step in the production line, it’s where precision, chemistry, and experience come together to define your final recovery.

When done right, it’s efficient, predictable, and profitable. When done poorly, it quietly drains value from every ton of ore mined.

That’s why choosing the right elution partner matters.

At Bulawayo Elutions, we treat every batch as a test of our craft, ensuring you get maximum gold, minimum loss, and complete peace of mind.