If mining is about digging, elution is about delivering.

It’s the moment where the hidden gold you’ve worked so hard to recover finally leaves the carbon and starts its journey toward becoming pure metal.

A lot of people talk about gold elution, but few truly understand what happens inside those columns, tanks, and pipes. This article breaks it down in plain language, the science, the sequence, and why precision at each step is the difference between an average recovery and an exceptional one.

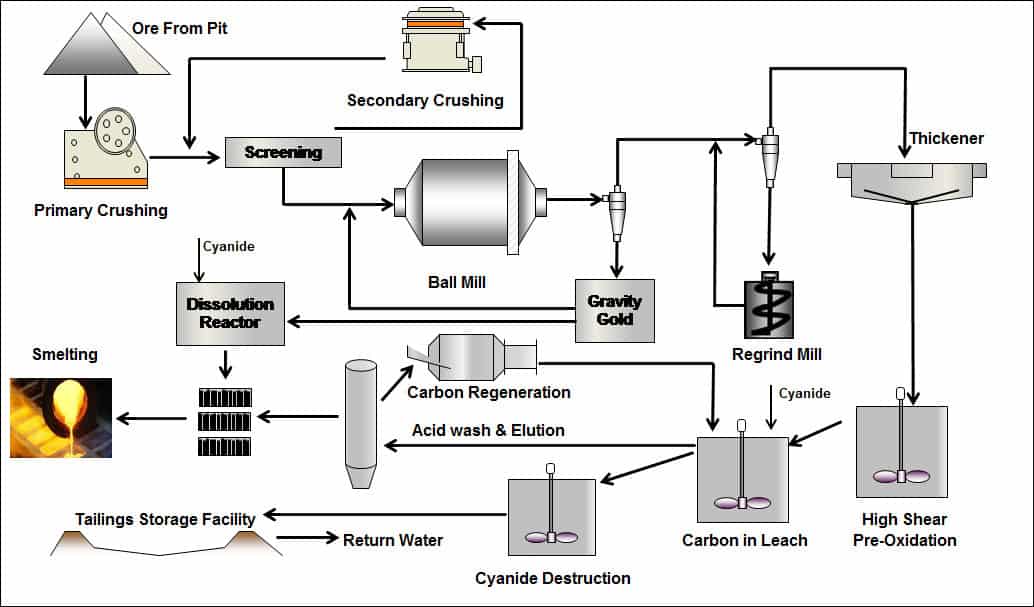

1. The Journey Begins: Loaded Carbon Enters the Elution Column

After gold is adsorbed onto activated carbon during the leaching process, the carbon becomes “loaded.”

Think of it like a sponge soaked in gold-bearing solution. Before you can get the gold out, you have to “squeeze” that sponge, and that’s exactly what the elution process does.

The loaded carbon is first screened, washed, and sized to remove any dust or debris. Then it’s transferred to a steel elution column, usually equipped with heating coils and flow control valves.

At this stage, everything depends on temperature, pressure, and flow rate, the three main pillars of efficient gold stripping.

2. The Strip Solution: Chemistry in Motion

The elution process uses a special solution known as the strip liquor, typically made from:

-

Sodium hydroxide (NaOH), to break chemical bonds between the gold and carbon.

-

Sodium cyanide (NaCN), to dissolve the gold ions into liquid form.

This solution is heated (usually between 110°C and 130°C) and pumped through the column under controlled pressure. The heat energizes the system, allowing the gold to desorb, or detach, from the carbon surface.

In simpler terms:

The hot, caustic solution “pulls” the gold molecules off the carbon and carries them away in a rich, gold-loaded liquid known as the pregnant solution.

3. The Electrowinning Stage: Capturing the Gold

Once stripped, the pregnant solution moves to the electrowinning cell.

Here, electricity takes over where chemistry leaves off.

-

The solution flows between steel wool cathodes and anode plates.

-

A controlled electrical current causes the dissolved gold to plate onto the steel wool.

-

Over time, fine layers of metallic gold build up, ready for collection.

This stage is a perfect balance of voltage, current density, and time. Too much power and you risk impurities; too little and recovery slows down. Skilled operators know how to fine-tune electrowinning cells for maximum yield with minimum waste.

4. The Final Step: Smelting and Purification

Once the gold has been collected from the electrowinning cell, the steel wool is washed, dried, and burned off in a furnace, leaving behind gold powder mixed with minor impurities.

That powder is then smelted in a crucible with flux, often borax and soda ash, to remove base metals.

The result: a doré bar containing mostly gold and a small amount of silver.

From there, it can be refined further to 99.99% purity, depending on the client’s requirements.

5. The Unsung Hero: Carbon Reactivation

After elution, the carbon isn’t thrown away. It’s reactivated, usually by heating in a kiln at around 650°C. This burns off any organic contaminants and restores the carbon’s adsorption power for reuse.

Good carbon management is key. Reusing poorly regenerated carbon can cause gold losses in future leach circuits, a mistake that costs mines real money over time.

6. A Matter of Precision

Every stage in elution, from heating to flow rate, relies on careful control.

Too much variation and you lose gold; too little attention and you lose consistency.

That’s why experience matters. At Bulawayo Elutions, we’ve refined our process parameters through years of real-world operation. We monitor every batch using calibrated instruments and strict temperature control to ensure gold recovery remains high and repeatable.

We don’t rely on guesswork. We rely on data, experience, and discipline, because every gram counts.

Why This Process Sets Us Apart

Many facilities can run an elution system, but not all can deliver consistent, clean results every time.

Our difference comes down to three things:

-

Speed: Our setup allows faster turnaround without compromising recovery.

-

Accuracy: We measure every step to ensure no gold is left behind.

-

Trust: Each batch is logged, tracked, and verified with our clients, transparency from start to finish.

When you bring your loaded carbon to us, you’re not just getting a service, you’re getting a partner that understands the value of every single ounce.

Final Thoughts

The gold elution process is more than just chemistry, it’s precision engineering.

From the first flush of hot solution to the final doré bar, it’s a system built on balance, expertise, and trust.

Every mine can dig up gold. But only those who master the art of elution turn it into dependable profit.